- Contact

- Automotive

- Medical

- About

- Home

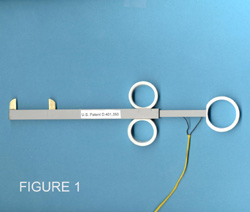

A prototype of the fully disposable, single use unit shown in Figure 1,

is the most elementary embodiment of the group of instruments. It has only

one moving part, the inner barrel, which is actuated by the thumb of the user.

While the blade faces are shown perpendicular to the barrel, the faces may be

manufactured at various angles and lengths to facilitate use.

one moving part, the inner barrel, which is actuated by the thumb of the user.

While the blade faces are shown perpendicular to the barrel, the faces may be

manufactured at various angles and lengths to facilitate use.

The finger rings may also be configured differently and mounted on the sides of the outer barrel. The thumb ring on the end of the inner barrel may also be mounted correspondingly.

The handpiece is constructed using plastic with metal blades. Blades with TeflonŽ coating, elastomeric silicone coating or stainless steel inner blades insulated or "sandwiched " between insulating layers may be utilized. It can be sterilized and packaged. After use it is disposed of appropriately.

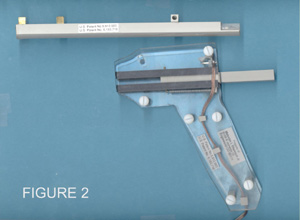

The novel feature of this handpiece is that the barrel is attached prior to use and

then disposed of after use. The actuator can be made of heavy molded plastic or

autoclavable metal if desired. Figure 2 shows the barrel prior to attachment to the

actuator. The barrel features a similar construction to that of the single use unit

but it includes an electrical connector that plugs into the actuator handle which is

connected to the power unit. Also provided is a means to connect the sliding inner

barrel and movable jaw to the thumb actuator in the handle. The barrel can be secured

to the handle unit by various means. On the prototype in Figure 2, it is a set screw.

However, a clip-type mechanism can be used.

then disposed of after use. The actuator can be made of heavy molded plastic or

autoclavable metal if desired. Figure 2 shows the barrel prior to attachment to the

actuator. The barrel features a similar construction to that of the single use unit

but it includes an electrical connector that plugs into the actuator handle which is

connected to the power unit. Also provided is a means to connect the sliding inner

barrel and movable jaw to the thumb actuator in the handle. The barrel can be secured

to the handle unit by various means. On the prototype in Figure 2, it is a set screw.

However, a clip-type mechanism can be used.

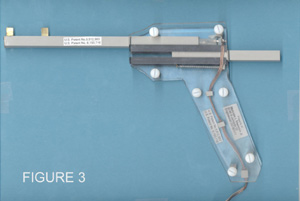

Figure 3 illustrates the barrel mounted in the actuator handle ready for use.

When the actuator is pressed by the thumb of the user the inner barrel and the movable

jaw closes toward the fixed jaw until the tissue is cut and cauterized. The actuator and

inner barrel are returned to the full open position after use by an elastic force

attached to the actuator. (In the prototype in Figure 3, a spring was used)

Figure 3 illustrates the barrel mounted in the actuator handle ready for use.

When the actuator is pressed by the thumb of the user the inner barrel and the movable

jaw closes toward the fixed jaw until the tissue is cut and cauterized. The actuator and

inner barrel are returned to the full open position after use by an elastic force

attached to the actuator. (In the prototype in Figure 3, a spring was used)

Utilization of a thumb actuator increases manual control leaving the index finger free to manipulate the handle allowing greater control. The thumb actuator has advantages over an index finger trigger actuator. One advantage is that it is comprised of less parts. Another is that a trigger would require additional space in the front of the handle for the trigger and its movement. Extra care would be required by the user in positioning a handle with an index finger trigger design to prevent premature actuation upon contact of the instrument with the patient's mouth. Even if this design were equipped with a "trigger guard," less manual control would be afforded the user due to the increased space necessary between the guard and patient's lip or jaw.

While the initial expense of purchasing the actuator will be slightly greater for the practitioner than with the fully disposable unit, the replacement barrels should be more inexpensive on a unit basis. Once a practitioner has purchased a multi-use actuator continuing orders for the replacement barrels should be assured from those practitioners.

Attachable/detachable barrels allow the manufacturer to offer variations in length, blade design and angle, etc. The separate actuator also allows it to serve as a handle for other barrel/blade configurations later developed for other surgical procedures.

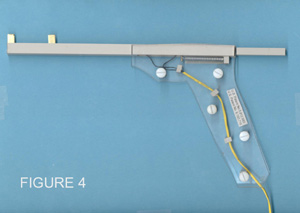

This embodiment is a combination of the features of the previous two designs. The prototype

in Figure 4 shows that a similar barrel design is utilized, but with direct thumb actuation of

the inner barrel. The barrel is made separately then placed in a molded plastic handle during

manufacture. See Figure 4. An elastic return means is used to return the movable inner barrel

and jaw to the preactuation position. In Figure 4, a spring is utilized. While this embodiment

may prove to be more expensive on a unit basis, it may be selected by some practitioners who

find the control of the handle/thumb actuator desirable but still prefer a fully disposable unit.

the inner barrel. The barrel is made separately then placed in a molded plastic handle during

manufacture. See Figure 4. An elastic return means is used to return the movable inner barrel

and jaw to the preactuation position. In Figure 4, a spring is utilized. While this embodiment

may prove to be more expensive on a unit basis, it may be selected by some practitioners who

find the control of the handle/thumb actuator desirable but still prefer a fully disposable unit.

The figures in the utility Patents show more details of the internal wiring configuration of the barrel which was not illustrated in the previous Figures. However, it should be recognized that the wiring configuration is slightly different for the various embodiments.